Advantages and Disadvantages of Compression Molding make it an essential consideration for manufacturers deciding on the best molding process for their needs. This technique offers a range of benefits, such as the production of strong, durable parts, while also presenting certain limitations that may affect cost and efficiency. In this article, we will delve into the various advantages and disadvantages of compression molding, comparing it with other molding processes like injection and cast molding to provide a clear understanding of its suitability for different applications.

What Is Compression Molding?

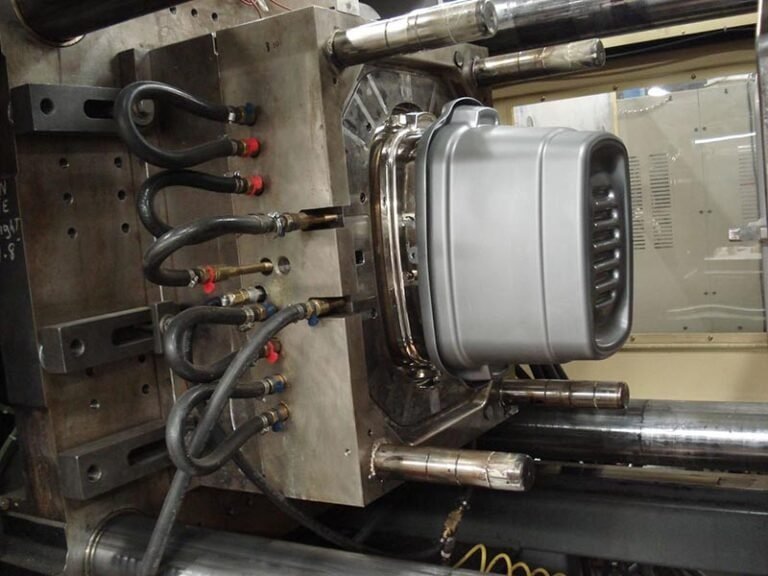

Compression molding services is a manufacturing process designed to create high-strength, durable components by shaping heated materials within a mold cavity. This method, widely used in the production of thermoset plastics and rubbers, relies on the application of heat and pressure to form the desired shape. The process is particularly effective for producing complex, large parts that require exceptional strength and integrity.

By leveraging the advantages of compression molding, industries such as automotive, aerospace, and consumer goods have achieved significant cost and material efficiency. Its adaptability to various materials, including thermosetting polymers and composite fibers, underscores its versatility in modern manufacturing.

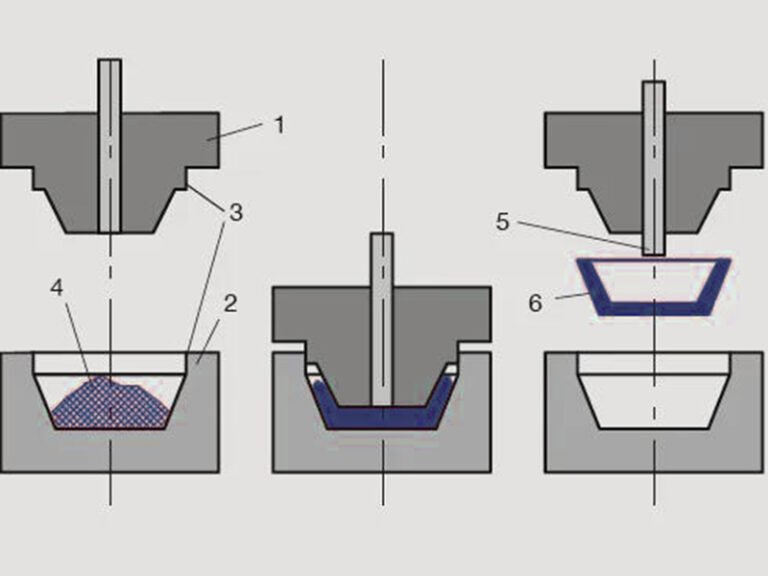

Compression Molding Techniques

Cold Compression Molding

Cold compression molding is primarily employed for materials that do not require preheating. In this technique, the raw material is placed directly into the mold cavity, which is subsequently compressed at room temperature. This method is ideal for applications where heat-sensitive materials are used, offering reduced energy consumption and material degradation.

Hot Compression Molding

Hot compression molding involves preheating the material before placing it in the mold. The combination of heat and pressure ensures the material flows uniformly, filling every cavity to achieve a precise shape. This technique is preferred for high-performance components that demand enhanced durability and strength, making it common in the automotive and aerospace industries.

Advantages of Compression Molding

Cost-Effective for Low-Volume Production

One of the key advantages of compression molding is its cost-efficiency, especially for small to medium production runs. The initial setup and tooling costs are lower compared to other molding techniques, making it an accessible option for companies with limited budgets.

Capability to Produce Large and Complex Parts

Compression molding excels in manufacturing large and intricate components that might be challenging with other methods. The process allows for the creation of robust parts with minimal material waste, ideal for applications like automotive body panels and industrial machinery parts.

Reduced Material Waste

Compared to injection molding, compression molding generates less scrap material. The exact amount of raw material required can be calculated and applied, minimizing wastage and contributing to sustainable manufacturing practices.

High Durability and Strength

Parts produced through compression molding exhibit superior mechanical properties. The combination of pressure and heat ensures that the material cures thoroughly, resulting in components with excellent strength, durability, and resistance to wear.

Disadvantages of Compression Molding

Limited Precision for Complex Geometries

While compression molding can handle large and simple parts well, it struggles with intricate geometries requiring fine details. The process may result in dimensional inconsistencies, especially when dealing with tight tolerances.

Longer Cycle Times

Compression molding typically involves longer cycle times compared to injection molding. The heating, curing, and cooling stages can be time-intensive, which may impact production speed in high-demand scenarios.

Labor-Intensive Process

The manual handling required during material placement and mold closure adds to labor costs. This factor can make compression molding less appealing for operations seeking automation and reduced workforce dependence.

Compression Molding vs. Injection Molding vs. Casting: Key Differences and Considerations

When discussing the advantages and disadvantages of compression molding, it’s important to also consider how it differs from other common molding methods such as injection molding and casting. Compared to injection molding, compression molding is typically more cost-effective with simpler mold designs, but it tends to have slower production speeds. On the other hand, casting is better suited for complex shapes and large-volume production. Each molding method has its own unique advantages, and the choice depends on factors such as material properties, production quantities, and cost efficiency.

Compression Molding vs. Injection Molding Parts Services

Compression molding and injection molding cater to distinct manufacturing needs. Injection molding offers faster cycle times and exceptional precision, making it the go-to method for mass production and intricate designs. In contrast, the advantages of compression molding, such as reduced setup costs and its ability to process large components, make it suitable for specialized applications.

While injection molding surpasses compression molding in automation and scalability, the latter stands out in scenarios demanding cost efficiency for smaller runs or high-strength parts. Understanding the advantages of rubber injection moulding over compression moulding is essential when selecting the appropriate method for a specific project.

| Aspect | Compression Molding | Injection Molding |

|---|---|---|

| Process | Involves placing preheated material into a mold and compressing it to form the shape. | Melts the material and injects it into a mold cavity under high pressure. |

| Best for | Large, simple, or durable components; low to medium production volumes. | Intricate, precise parts; high-volume production. |

| Material Usage | Uses a calculated amount of material with minimal waste. | Can lead to material wastage due to runners, sprues, and excess flash. |

| Cycle Time | Typically longer due to heating, curing, and cooling stages. | Shorter cycle times, enabling faster production. |

| Tooling Cost | Lower initial tooling costs, making it cost-effective for small runs. | Higher tooling costs, but economical for large-scale production. |

| Detail and Precision | Less suitable for parts requiring high precision or fine details. | Excels at creating complex geometries and tight tolerances. |

| Material Compatibility | Works well with thermosetting plastics and rubbers. | Ideal for thermoplastics but can also handle some thermosets. |

| Part Strength | Produces highly durable parts with strong mechanical properties. | Parts are typically less strong compared to those made via compression molding. |

| Automation | Usually more manual, leading to higher labor involvement. | Highly automated, reducing labor costs and increasing efficiency. |

| Applications | Automotive body panels, industrial machinery parts, large seals, and electrical insulators. | Consumer electronics, medical devices, automotive components, packaging, and household items. |

| Production Scalability | Suitable for low-to-medium volume production. | Designed for mass production, offering cost advantages at higher volumes. |

| Energy Consumption | Generally lower as preheated materials are directly molded. | Requires more energy to melt the material and maintain high-pressure injection systems. |

| Surface Finish | May require post-processing to achieve smooth surfaces. | Produces smoother finishes, often eliminating the need for additional processing. |

Compression Molding vs. Cast Molding Parts Services

Compression molding and cast molding share similarities in their ability to shape materials under pressure. However, they differ significantly in execution. Compression molding utilizes heat and pressure within a mold cavity, while cast molding involves pouring liquid material into a mold and allowing it to cure at ambient or controlled temperatures.

Cast molding is better suited for intricate, low-volume applications due to its ability to replicate fine details. Conversely, compression molding shines in producing large, durable parts for demanding industries. Each technique has its unique advantages and disadvantages, influencing its application based on project requirements.

| Aspect | Compression Molding | Cast Molding |

|---|---|---|

| Process | Involves placing preheated material into a heated mold and compressing it to shape. | Material is poured or injected into a mold and allowed to cure without applied pressure. |

| Best for | Durable parts with consistent mechanical properties; high-strength components. | Large or intricate parts where fine details are essential; suitable for prototypes. |

| Material Usage | Uses a predetermined amount of material with minimal excess. | Typically involves more material wastage due to trimming and overflow. |

| Cycle Time | Faster cycle times, as heat and pressure accelerate curing. | Longer cycle times due to the curing process being dependent on material chemistry and temperature. |

| Tooling Cost | Requires moderately priced tooling with durable molds. | Lower tooling costs, as molds are often simpler and less robust. |

| Detail and Precision | Produces durable parts but with limited detail resolution. | Ideal for high-detail parts, as the material flows freely into intricate mold cavities. |

| Material Compatibility | Commonly used with thermosetting plastics and rubbers. | Compatible with a wide range of materials, including resins, metals, and elastomers. |

| Part Strength | Produces high-strength parts with excellent mechanical properties. | May result in parts with less structural integrity compared to compression molding. |

| Surface Finish | Surface finish may vary and often requires additional processing. | Achieves superior surface finishes due to the free-flowing nature of the material. |

| Labor Intensity | More manual labor may be required for mold loading and unloading. | Generally less labor-intensive, as the process can rely on gravity or simple machinery. |

| Applications | Automotive components, industrial seals, and heavy-duty machinery parts. | Artistic items, decorative pieces, dental molds, and prototypes requiring intricate details. |

| Production Scalability | Suitable for medium-scale production runs with consistent output. | Best for low-volume production, custom parts, and prototypes. |

| Energy Consumption | Moderate energy consumption due to heating and compression stages. | Lower energy usage since pressure is not applied, relying on natural curing. |

Conclusion

Compression molding remains a cornerstone of modern manufacturing, offering a unique balance of cost-efficiency, strength, and versatility. While the process has its limitations, its ability to produce durable, large-scale components makes it indispensable for industries like automotive and aerospace. By weighing the advantages and disadvantages of compression moulding against other techniques, manufacturers can make informed decisions tailored to their production needs. As advancements in materials and technology continue, the future of compression molding promises greater precision and sustainability.