Automotive rubber bellows, also known as rubber boots or dust boots, are essential components in various automotive systems, providing protection, sealing, and vibration absorption. Due to their flexible, durable, and protective properties, automotive rubber bellows have different functions, like helping with steering and suspension protecting engines and exhausts, keeping dirt out, reducing vibrations, and making sure everything runs smoothly. In this article, we will explore the applications of rubber bellows in the automotive industry, and learn how they protect the automotive components work in safe environments.

The Benefits of Automotive Rubber Bellows

Protection of Components: Rubber bellows are used to protect critical automotive components such as steering systems, pumps, pistons, shafts, and guideways from dirt, debris, and other contaminants. This helps extend the lifespan of these components.

Vibration Absorption: The flexible, accordion-like design of rubber bellows allows them to absorb vibrations and minimize mechanical noise in various automotive applications, leading to a smoother and more comfortable driving experience.

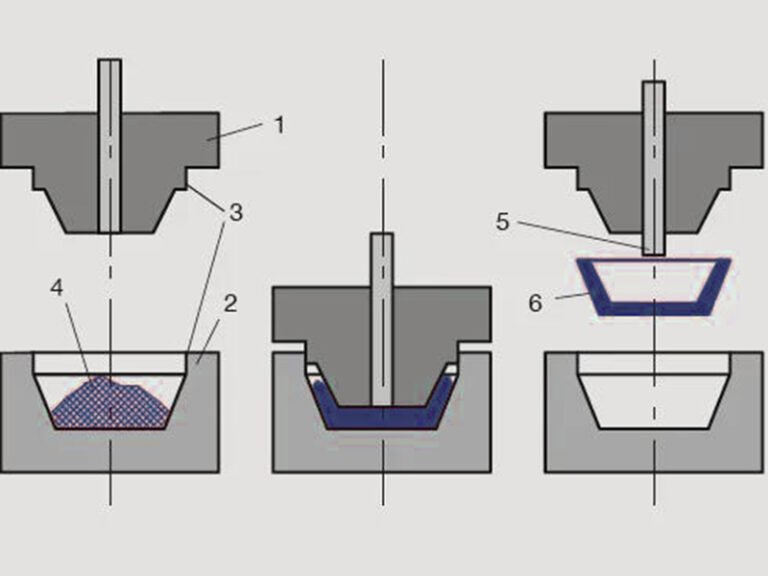

Sealing and Containment: Rubber bellows create a flexible seal that can withstand high-pressure changes, helping to reduce friction between mating parts and prevent the ingress of corrosive substances like oils, acids, and condensation. This contributes to improved durability and reduced maintenance needs.

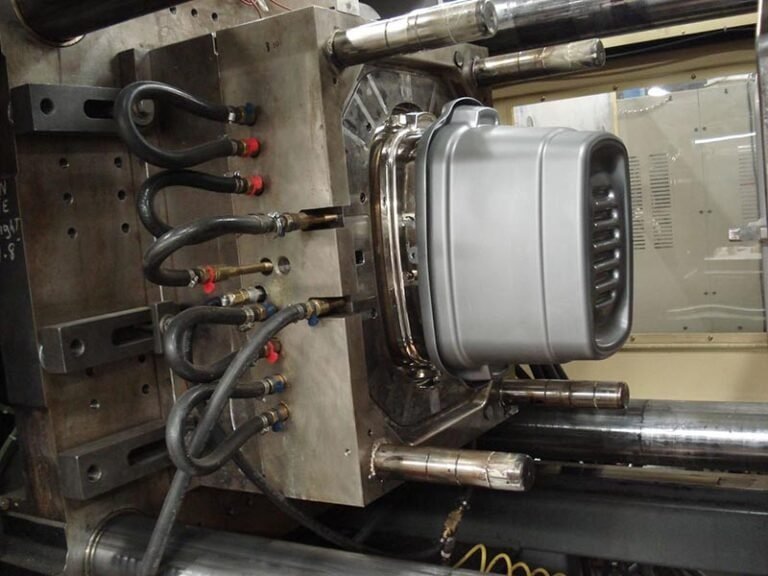

Customization: Rubber bellows can be customized in terms of shape, size, and material properties to meet the specific requirements of different automotive applications, ensuring optimal performance and integration.

Enhanced Efficiency and Performance: By protecting components, absorbing vibrations, and providing reliable sealing solutions, rubber bellows contribute to improved efficiency, smoother operation, and overall cost-effectiveness within automotive systems.

Sustainability: Rubber bellows can be manufactured using eco-friendly materials, contributing to a greener industry footprint by reducing the need for frequent replacements and supporting the overall sustainability of automotive systems.

The Applications of Automotive Rubber Bellows

Steering Systems: Rubber bellows are often used in steering systems, particularly in steering rack and pinion setups. They are placed over the ends of the steering rack to seal the inner components from dust, dirt, and debris. This helps to prevent contamination and maintain the smooth operation of the steering system.

Suspension Systems: In automotive suspension systems, rubber bellows are employed to protect the inner components, such as shock absorbers and struts, from external elements like dirt, water, and road debris. This helps to prolong the lifespan of the suspension components and ensures optimal performance.

CV (Constant Velocity) Joints: Rubber bellows are integral components of CV joints, which are used in front-wheel-drive and all-wheel-drive vehicles. These bellows are placed over the CV joint to protect it from contamination and to retain the grease lubricant inside. They also allow for the articulation of the joint as the vehicle’s suspension moves.

Drive Shaft Boots: Rubber bellows are used to cover and protect the joints on drive shafts, which transmit power from the transmission to the wheels. These boots prevent grease leakage and keep out contaminants, ensuring smooth and efficient power transfer.

Air Intake Systems: In some vehicles, rubber bellows are used in the air intake system to connect the air filter housing to the throttle body or intake manifold. They provide flexibility to accommodate engine movement and vibrations while sealing the system to prevent the ingestion of debris and contaminants.

Exhaust Systems: Rubber bellows can be found in exhaust systems where they are used to absorb vibrations and movements between exhaust components, such as between the exhaust manifold and the exhaust pipe. They help to reduce stress on the exhaust system and minimize the transmission of vibrations to the vehicle chassis.

Engine Mounts: Rubber bellows are utilized in engine mounts to dampen vibrations and isolate the engine from the rest of the vehicle’s structure. They help to improve ride comfort and reduce noise transmission from the engine to the passenger compartment.

Lead Screws: Lead screws are commonly used in automotive applications for precise linear motion, such as in adjusting seats or controlling vehicle components. Rubber bellows can be used to protect lead screws from external elements and debris, ensuring smooth and accurate operation.

Cylinders: Rubber bellows are utilized in various automotive cylinders, including brake cylinders and hydraulic cylinders. They act as seals to prevent fluid leakage and contamination, ensuring proper functioning and longevity of the cylinder components.

Overall, rubber bellows play crucial roles in various automotive applications, and enhance the performance, durability, and reliability of automobiles. Erye Rubber & Plastic has customized various automotive rubber bellows. Get in touch to start your rubber bellow projects!