A bushing is a mechanical component used to reduce friction and wear between two moving parts. It is typically made from materials such as metal, rubber, or polymer, depending on the specific application requirements. Bushings are commonly used in machinery, automotive applications, and various other mechanical systems to provide support, reduce vibration, and allow for smooth rotation or movement. They can also be used to compensate for any misalignment between components.

Common Materials Used to Make Bushings

Bronze:

Bronze Bushings are known for their excellent wear resistance, high load capacity, and low friction.

Commonly used in heavy-duty applications such as industrial machinery, automotive components, and equipment where durability and reliability are critical.

Brass:

Brass Bushings offer high corrosion resistance, good wear resistance, and low friction.

They are often used in applications with paramount corrosion resistance, such as marine environments, plumbing fixtures, and electrical connectors.

Steel:

Steel Brushings are durable materials with high load capacities, though they can be susceptible to corrosion.

Widely employed in heavy machinery, construction equipment, automotive parts, and precision tools due to its strength and reliability.

Plastic/Polymer Materials:

Various plastics and polymers, including nylon, polyethylene, PTFE (Teflon), PEEK, PPS (Ryton), and UHMW PE, are used for bushings. bushing material selection with us!

These materials offer low friction, lightweight properties, and resistance to wear, making them suitable for diverse applications ranging from automotive components and consumer products to office equipment and machinery.

Metal Matrix Composites:

Metal matrix composites combine the properties of metals and ceramics to provide superior wear resistance and high load capacity.

These bushings can withstand extreme temperatures and harsh operating conditions, making them suitable for aerospace, defense, automotive racing, and other demanding applications where durability and performance are paramount.

The Different Types of Bushings

Several different types of bushings are used in machinery to provide a bearing surface that reduces friction between two components. Here are the most common types of bushings:

Plain Bushings: Plain bushings, also known as sleeve bearings, are the simplest type of bushings. They are cylindrical sleeves. Plain bushings provide low-friction support and are commonly used in applications where radial loads need to be supported.

Ball Bearing Bushings: Ball bearing bushings contain ball bearings within their structure to support axial and radial loads. These bushings offer higher load capacities and reduced friction compared to plain bushings. That makes them suitable for applications with more demanding operating conditions.

Roller Bushings: Roller bushings utilize cylindrical rollers instead of balls to support axial and radial loads. These bushings offer improved load distribution and higher load capacities compared to ball-bearing bushings. They are ideal for heavy-duty applications such as conveyor systems and machinery.

Flanged Bushings: Flanged bushings feature a flange or collar on one end, which serves to locate the bushing axially and provide additional support. The flange helps prevent axial movement of the bushing and provides a surface for mounting or securing other components.

Split Bushings: Split bushings, also known as split sleeve bearings, are designed to be easily installed and removed without disassembling the equipment. These bushings consist of two parts that can be separated, allowing for convenient maintenance and replacement.

Linear Bushings: Linear bushings are specialized bushings designed to provide linear motion with minimal friction. They are commonly used in applications such as linear motion systems, machine tools, and automation equipment to guide and support moving components along a linear path.

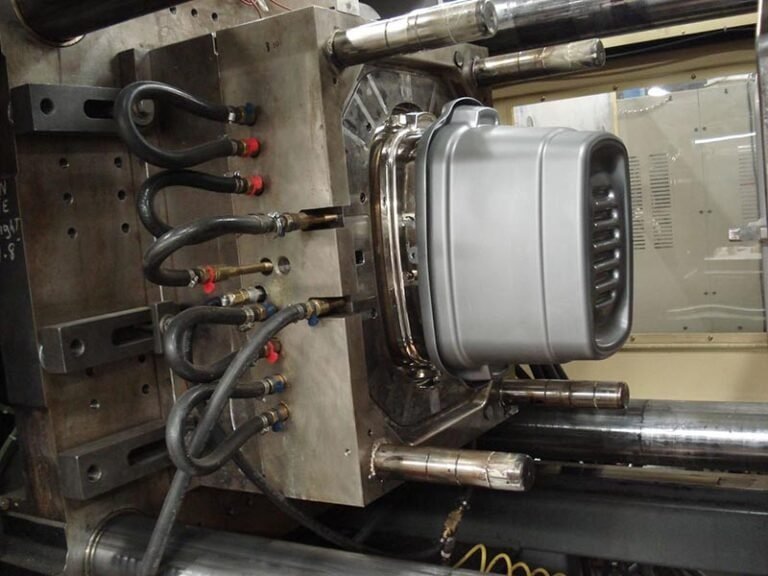

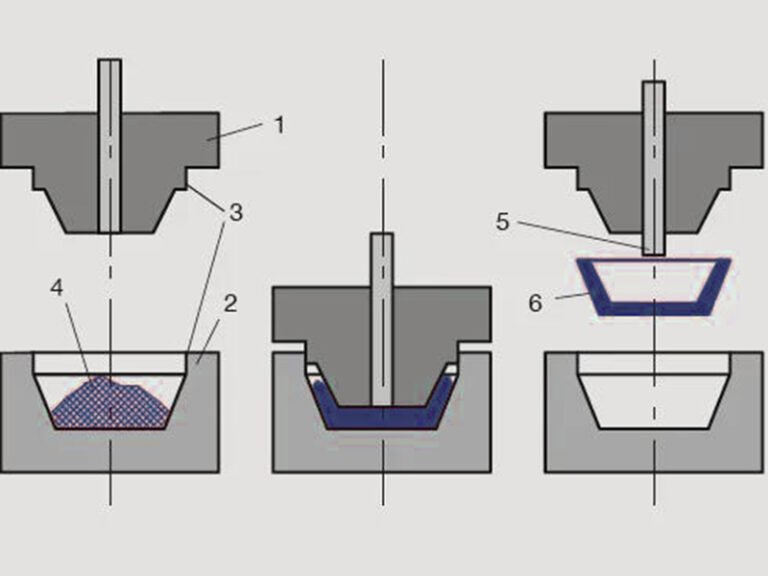

Custom Bushings: Custom molding bushings are tailored to meet specific design requirements and application needs. They can be designed with unique dimensions, materials, and features to optimize performance and compatibility with the surrounding components.

Different Types of Bushings by Material

Bronze Bushings: Bronze bushings are made from bronze or a bronze alloy and are known for their excellent wear resistance and self-lubricating properties. They are often used in high-load and high-temperature applications where lubrication may be limited or impractical.

Ceramic Bushings: Ceramic bushings are constructed from ceramic materials such as silicon nitride or zirconia. They offer superior wear resistance, corrosion resistance, and thermal stability compared to metal or polymer bushings, making them suitable for demanding applications in harsh environments.

Rubber and Elastomeric Bushings: Rubber and elastomeric bushings are made from flexible materials such as rubber or polyurethane. These bushings absorb vibration, dampen noise, and provide isolation from shock and impact, making them ideal for automotive suspension systems, machinery mounts, and vibration isolation applications.

Bushing Vs Bearing

Bushings and bearings are both mechanical components used to reduce friction and support rotating or moving parts within machinery and mechanical systems. While they serve similar functions, there are key differences between bearing and bushing:

Design:

Bushings are a single-component design, while bearings are multi-component with rolling elements like balls or rollers.

Materials:

Bushings are typically made from softer materials like rubber, plastic, or bronze, while bearings use harder materials like steel.

Friction and Lubrication:

Bushings generally have higher initial friction and require more lubrication than bearings. Bearings are designed to be more “frictionless” from the start.

Applications:

Bushings are better suited for lower-speed, higher-load applications like machinery and automotive suspension. Bearings are used in high-speed, high-precision applications like motors, pumps, and compressors.

Maintenance:

Bushings often require more frequent maintenance and lubrication than bearings.

Types of Bushing Conclusion

In conclusion, bushings may seem like small components, but they play an important role in the smooth operation and longevity of mechanical systems. Their ability to reduce friction, provide support, and absorb shocks makes them indispensable in various engineering applications. By understanding the materials and types of bushings, engineers can make informed decisions to optimize the performance and reliability of their designs.