In the world of machinery and engineering, components like bushing vs bearing are important for ensuring smooth operation and reducing friction. While they might seem similar at first glance, each serves different purposes and possesses unique characteristics. This article aims to explore the disparities between bushings and bearings in several parts.

The Different Between Bushing vs Bearing

Definition and Functionality:

Bushing: A bushing, also known as a plain bearing or sleeve bearing, is a cylindrical component designed to provide support and reduce friction between moving parts. Bushings are made from softer materials such as custom rubber or plastic molding material which can cushion a joint against shock while preventing metal-to-metal contact. Bushings often have grooves cut into their sides that act as lubrication ports for oil or grease which helps them move freely.

Bearing: Bearings are mechanical components that facilitate smooth motion by reducing friction between moving parts. Depending on the application, bearings come in many different shapes and sizes. Such as ball bearings, roller bearings, thrust bearings, etc. Bearings are generally made from harder materials such as steel or ceramic for better performance at higher speeds. Bearings are typically constructed from more durable materials than bushings, so they can withstand heavier loads or faster speeds for longer periods without wearing down too quickly than bushings.

Construction and Design:

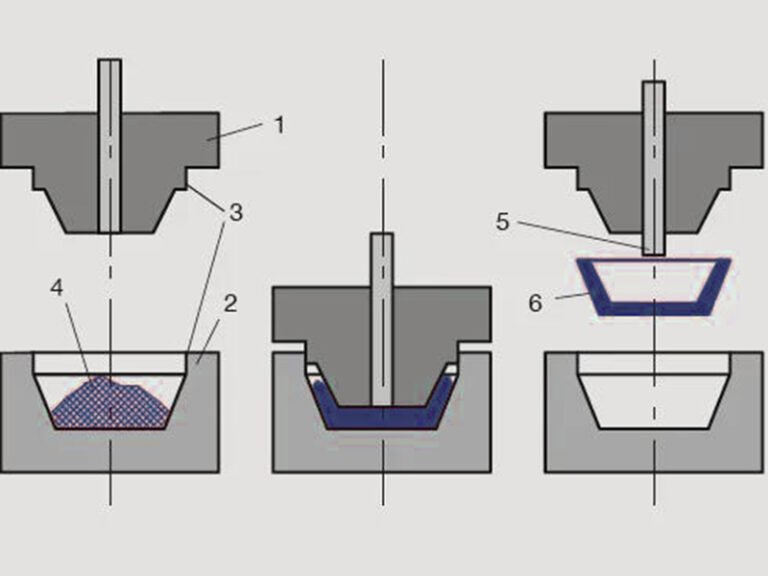

Bushing: Bushings are relatively simple in design, consisting of a hollow cylindrical shape with an inner diameter matching the shaft’s size and an outer diameter fitting into the housing or mounting surface.

Bearing: Bearings are more complex in construction, comprising multiple components like balls, rollers, cages, and inner and outer races. This intricate design allows bearings to accommodate different types of loads, speeds, and operating conditions.

Motion:

Bushings operate through a sliding motion between the bushing and shaft, where the shaft slides within the inner diameter of the bushing.

Bearings operate through a rolling motion between the inner and outer rings, with balls, rollers, or other elements rolling between the two rings to facilitate smooth movement.

Load Capacity and Performance:

Bushing: Bushings are generally preferred for light to moderate loads and low-speed applications due to their simple construction. They excel in providing smooth, low-friction movement in situations where precision is essential.

Bearing: Bearings are capable of handling heavier loads and higher speeds compared to bushings. Their complex design allows them to distribute loads more evenly, making them suitable for demanding industrial environments and high-performance machinery.

Precision and Accuracy:

Bushing: Bushings on the other hand, generally have lower manufacturing tolerances, resulting in less precision compared to bearings. While adequate for many applications, bushings may not offer the same level of accuracy required for high-precision machinery or equipment.

Bearing: Bearings are known for their precision and accuracy, attributed to tighter manufacturing tolerances. This precision allows bearings to maintain consistent performance even under demanding conditions.

Lubrication and Maintenance:

Bushing: Bushings typically require regular lubrication to minimize friction and prevent wear. Without proper lubrication, bushings may experience increased friction, leading to premature failure and decreased performance.

Bearing: Bearings often come pre-lubricated or sealed to minimize maintenance requirements. However, certain types of bearings may require periodic lubrication or maintenance to ensure optimal performance and longevity.

Applications:

Bushing: Custom plastic bushings parts find applications in various industries, including automotive, aerospace, and manufacturing, where they are used in components like suspension systems, engine parts, and hydraulic cylinders.

Bearing: Bearings are ubiquitous in countless applications, ranging from household appliances and automotive components to heavy machinery and industrial equipment. They are indispensable in rotating machinery such as motors, pumps, and turbines.

Cost:

Bushing: Bushings are typically less expensive than bearings, making them a cost-effective choice for applications where precision requirements are less critical.

Bearing: Bearings typically have a higher initial cost due to their more complex design and manufacturing process. However, they often provide longer service life and lower overall maintenance costs, making them a more economical choice in the long run, especially for high-performance or heavy-duty applications.

Factors to Consider When to Choose the Components

Speed and Loading:

Determine the operating conditions regarding velocity and loading. Assess whether the application involves heavier loads at slower speeds or lighter loads at higher speed.

Bearings are generally more suitable for high-speed applications, where they excel in reducing friction and facilitating smooth motion.

Bushings, on the other hand, tend to perform better in low-speed scenarios with heavy loads, providing strong support and stability.

Smoothness of Operation:

Consider the importance of smooth operation in the application. Evaluate whether any “stick and slip” issues may arise during the operation.

Bearings typically offer smoother operation than bushings, thanks to their rolling motion mechanism, which minimizes friction and enhances efficiency.

Operating Noise:

Evaluate the impact of operating noise on the surrounding environment or equipment functionality.

Bushings generally produce less operating noise than bearings, making them suitable for noise-sensitive applications or environments where quiet operation is preferred.

Maintenance and Lubrication:

Consider the maintenance and lubrication requirements. In industries such as food processing, textiles, or cleanroom environments, where hygiene and low maintenance are paramount, consider options that offer self-lubrication or minimal maintenance requirements.

Bearings may require regular lubrication and maintenance, whereas certain types of bushings can operate without frequent lubrication, reducing downtime and maintenance costs.

Budget:

Finally, consider the budget and cost-effectiveness.

While bushings typically have a lower initial cost than bearings, it’s essential to weigh the long-term benefits and potential savings associated with each option.

Evaluate the overall lifecycle costs, including maintenance, replacement, and downtime expenses, to make an informed decision that aligns with budgetary considerations.

ERYE bushing and bearing Conclusion

While both bushings and bearings serve the fundamental purpose of reducing friction and facilitating smooth motion, they differ significantly in terms of design, load capacity, performance, and maintenance requirements. Understanding these differences is crucial for selecting the most suitable component for a particular application, ensuring optimal efficiency, reliability, and longevity in machinery and mechanical systems.

When deciding between bushings and bearings, it’s important to prioritize factors such as speed and loading, smoothness of operation, operating noise, maintenance requirements, and budget. By carefully considering these factors in order of importance, engineers and designers can choose the most suitable component for their specific application, ensuring optimal performance, reliability, and cost-effectiveness in the long run.