Pulleys are essential mechanical components used to lift, move, or transfer loads with minimal effort, playing a critical role in industries and everyday applications. Understanding the types of pulley and their functions enables engineers and designers to optimize systems for efficiency and durability. This article explores what are the different types of pulleys, their materials, applications, advantages, disadvantages, and considerations for custom designs, providing a comprehensive guide to the kinds of pulleys used today.

What Is a Pulley and How It Works?

A pulley is a simple machine consisting of a wheel with a grooved rim, mounted on an axle, through which a rope, belt, or chain passes to transfer force. The primary function of a pulley is to redirect force or reduce the effort required to move a load, leveraging mechanical advantage. The types of pulley determine the degree of force amplification, calculated as the number of rope segments supporting the load.

For example, a single fixed pulley changes the direction of force, requiring the same effort as the load weight (mechanical advantage = 1). A movable pulley, attached to the load, halves the effort needed (mechanical advantage = 2). By understanding how many types of pulley exist and their mechanics, users can select the appropriate configuration for specific tasks, such as lifting heavy materials or transmitting power.

How Many Types of Pulley?

The types of pulley encompass five distinct designs: fixed, movable, compound, block and tackle, and cone pulleys, each tailored to specific mechanical requirements. These kinds of pulleys enable diverse applications, addressing what are the different types of pulleys in lifting and power transmission.

Fixed Pulley

A fixed pulley is anchored to a stationary point, with the wheel rotating on a fixed axle. It redirects the force applied to the rope, making it easier to lift or move loads in a specific direction. For instance, pulling down on a rope to raise a flag uses a fixed pulley, maintaining a mechanical advantage of 1.

This type is common in applications like flagpoles or well systems, where changing force direction is the primary goal. However, it does not reduce the effort needed to lift the load, limiting its use for heavy objects.

Movable Pulley

A movable pulley is attached to the load itself, with one end of the rope fixed and the other pulled. This configuration doubles the mechanical advantage (2:1), halving the force required to lift the load. For example, a movable pulley in a crane system reduces the effort needed to hoist materials.

While effective for lifting, movable pulleys require more rope length and can be slower to operate, making them ideal for tasks prioritizing force reduction over speed.

Compound Pulley

A compound pulley, also known as a block and tackle, combines fixed and movable pulleys to achieve a higher mechanical advantage. By increasing the number of rope segments, it significantly reduces the effort needed. For instance, a compound pulley with four rope segments offers a mechanical advantage of 4, allowing a 100 kg load to be lifted with 25 kg of force.

This type is prevalent in heavy-duty applications, such as construction cranes or sailing rigs, but requires more space and complex setup. The different types of pulleys and their application highlight the compound pulley’s versatility for demanding tasks.

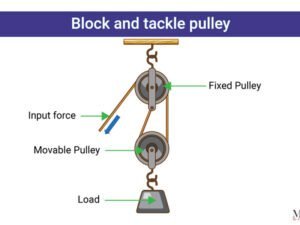

Block and Tackle Pulley

A specialized compound pulley with parallel fixed and movable pulleys, achieving a mechanical advantage of 3. Employed in heavy-duty hoists for construction, it optimizes load handling.

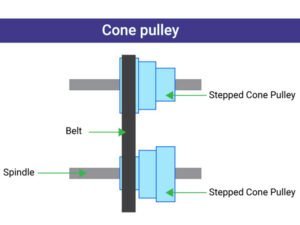

Cone Pulley

Comprising multiple pulleys in a conical arrangement, it adjusts motion speed through varying circumferences. Used in servo motor-driven systems, it supports variable-speed power transmission.

Types of Pulley Materials

Common pulley materials include steel, aluminum, stainless steel, nylon, and cast iron—each offering different advantages in strength, weight, and resistance. We can customize pulleys in various materials to meet your specific performance and environmental needs.

Applications of Pulleys

The types of pulley enable a wide range of applications, support diverse fuctions. They are simplifying tasks in both industrial and everyday settings.

- Elevators: Compound pulleys lift heavy cabins, ensuring smooth and efficient vertical transport in buildings.

- Construction Cranes: Block and tackle pulleys hoist steel beams or clear debris, reducing the force needed for heavy lifting.

- Fitness Equipment: Movable pulleys in weight machines, like lat pull-down systems, enable safe and controlled resistance training.

- Curtains and Blinds: Fixed pulleys allow easy raising and lowering of window coverings or theater curtains with minimal effort.

- Well Water Retrieval: Movable pulleys facilitate pulling buckets from wells, a traditional application still used in rural areas.

- Sailboat Rigging: Compound pulleys adjust sails and control direction, optimizing force application in marine environments.

- Washing Machines: Flat belt pulleys connect motors to drums, enabling rotational motion for effective cleaning cycles.

- Climbing Equipment: Movable pulleys balance loads for rock climbers, enhancing safety and ease of ascent.

Advantages and Disadvantages of Pulleys

The pulley offer significant benefits but also face limitations, impacting their suitability for various applications.

Advantages

- Force Reduction: Movable and compound pulleys reduce effort, with mechanical advantages of 2 or higher (e.g., a compound pulley with MA=4 lifts 1000 kg using 250 kg force).

- Directional Flexibility: Fixed pulleys redirect force, enabling convenient operation, such as pulling down to lift a flagpole load.

- Cost and Noise: Simple to manufacture, kinds of pulleys are cost-effective and operate quietly, ideal for indoor settings.

- Safety and Maintenance: Operators remain distant from loads, enhancing safety, and pulleys require minimal lubrication post-installation.

Disadvantages

- Require Large Space Requirements: Compound pulleys demand significant space (e.g., 10 m rope length for MA=4, occupying 5 m²), limiting compact applications.

- Need Wear and Maintenance: Ropes and belts wear with use, requiring regular inspections to prevent breakage, especially in high-load systems.

- Slippage: Friction-based different types of pulleys and their application risk rope or belt slippage, reducing efficiency in non-grooved wheels.

- Power Limitations: Pulleys are less effective for high-speed or high-power transmission, where gears are preferred, and heavy loads demand multiple pulleys, increasing costs.

Custom Pulleys from Flexiparts

For applications requiring specific performance, custom pulleys offer tailored solutions to meet unique load, speed, or environmental demands. Design considerations include wheel diameter and groove size to ensure compatibility with ropes or belts, material selection (e.g., stainless steel for marine use or nylon for low-friction systems), and load capacity to achieve the desired mechanical advantage.

Flexiparts provides comprehensive custom pulley manufacturing, leveraging advanced techniques like CNC milling and die casting to produce durable, application-specific components. These methods ensure tight tolerances and material consistency, enhancing the performance of different types of pulleys and their application in industries from construction to automation.