An optical module dustproof plug is a simple yet essential component that is crucial in safeguarding optical modules from the detrimental effects of dust and other contaminants, ensuring their optimal performance and durability. This post will explore these simple molded parts and learn their materials, types, applications, and benefits.

What is Optical Module Dustproof Plug?

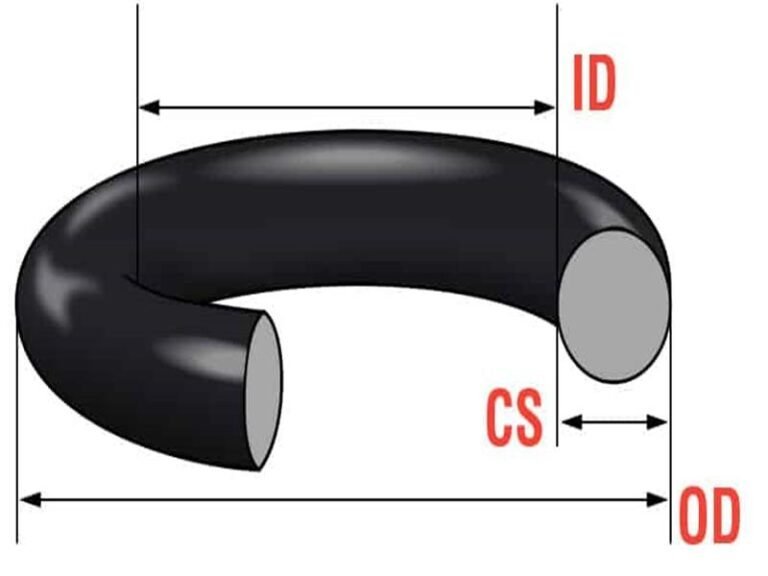

An optical module dustproof plug is a protective component specifically designed to prevent dust and other particulate matter from entering and contaminating optical modules. These plugs are typically made from materials like silicone, rubber, or plastic, which are chosen for their durability and sealing properties. The primary function of the plug is to create a barrier that shields the sensitive optical elements within the module from external contaminants.

Common Materials Used for Optical Module Dust Plugs

Optical module dust plugs are essential for protecting the delicate components of fiber optic systems. These plugs are made from various materials, each offering unique benefits. Here are some of the most common materials used:

1. Plastic

Common plastics include polyethylene (PE), polypropylene (PP), and polycarbonate (PC). Plastic dust plugs are cost-effective and lightweight. They provide a good seal against dust and debris and are easy to manufacture in various shapes and sizes to fit different optical modules. While effective against dust, plastic plugs may not offer the same protection against moisture or electromagnetic interference as metal plugs.

2. Metal

Metals such as aluminum and stainless steel are often used. Metal dust plugs are more durable and protect against environmental factors such as electromagnetic interference and mechanical damage. They are often used in more demanding environments. However, metal plugs are generally more expensive and heavier than plastic plugs. They may also require additional features like chains to prevent loss.

3. Rubber

Rubber dust plugs are highly effective at sealing out dust and moisture. They are elastic, which helps them fit snugly and securely into optical module ports. This elasticity also makes them less likely to be accidentally dislodged, providing better mechanical protection and extending the lifespan of the optical module. However, rubber plugs can degrade over time, especially when exposed to harsh environmental conditions. They may also be more expensive than basic plastic plugs.

Benefits of Dustproof Plug for Optical Module

1. Prevent Dust from Entering the Optical Module

Dustproof plugs create a tight seal that effectively blocks dust and other particulate matter from entering the optical module. This is crucial for maintaining the cleanliness of the optical interfaces, ensuring optimal signal transmission, and reducing the risk of signal degradation.

2. Prevent Water Vapor in the Air from Entering the Optical Module

Dustproof plugs can prevent water vapor and humidity from entering the optical module. This is particularly important in environments with high humidity levels, as moisture can cause corrosion and other forms of damage to sensitive optical components.

3. Prevent Oxidation of the Optical Module in Contact with Air

Exposure to air can lead to oxidation of the metallic parts of optical modules. Dustproof plugs provide an effective barrier against air, thereby reducing the risk of oxidation. This helps in maintaining the performance and longevity of the optical module.

4. Prevent Other Conductors from Entering the Optical Module and Causing a Short Circuit

Optical module plugs can prevent conductive materials from entering the optical module, thereby reducing the risk of short circuits and electrical failures. This is especially important in environments where there are multiple electronic components nearby.

5. Preventing mechanical damage:

Dustproof plugs protect sensitive optical components from physical damage that could occur during handling, storage, or transportation and extend the operational life of optical modules.

Types of Dustproof Plugs

There are several types of dustproof plugs available in the market for optical modules and other electronic devices. Here’s an overview of the different types and materials commonly used:

Types Based on Materials:

Silicone plug: A popular material for dustproof plugs due to its flexibility, durability, and ability to create a tight seal. Silicone plugs are effective in protecting ports from dust, liquid, and other contaminants.

Plastic plug: Often used for cost-effective and lightweight dustproof plugs. Plastic plugs can be easily manufactured in various shapes and sizes to fit different ports.

Zinc plug: Metal plugs, such as those made from zinc, offer durability and are suitable for more demanding environments. They are particularly used for QSFP and XFP connectors.

Types based on shape

dustproof plugs are available for both single-mode and multi-mode fiber optic connectors, each designed to protect the specific type of connector.

Types based on port compatibility:

- Audio jack plugs: Designed to fit into headphone or microphone ports.

- Power port plugs: Specifically shaped to protect charging ports.

- Type-C plugs: Silicone dust plugs are designed for USB Type-C charging ports.

- QSFP and XFP connector plugs: Specialized plugs for these types of optical module connectors, often made with zinc bodies.

Application of Dustproof Plug

- Applicable to optical modules,

- Applicable to optical terminals

- Applicable to optical modems

- Applicable to routers

- Applicable to optical transceivers

Conclusion

Dustproof plugs are essential components for protecting optical modules and other electronic devices from dust, moisture, and potential damage. Different materials and different types of dustproof plugs ensure that users can find the right fit for their needs. Welcome to contact to custom molded dustproof plug.