Gear manufacturers are known to switch from metal to plastic gears for high-power appliances (due to the latter’s advantages). However, one issue persisted: plastic gear noise. Continue reading to learn why this happens and how to reduce plastic gear noise!

Leading Causes of Plastic Gear Noise

Surface Finish

The surface of the gear teeth is one of the reasons that cause plastic gear noise. The tiny imperfections on an uneven surface can come into contact with each other while rotating. It causes friction and vibration, thus resulting in noise in plastic gear. The rougher your surface, the more noise the gears will make. You can observe it when the gears have been used for a long time.

Engagement Errors

If the gears are not aligned properly, the teeth might not mesh as they usually do. The teeth will rub against each other in this case.

Two gear teeth must leave the gear before the other teeth start engaging. When this does not happen, and the transition between the two rounds is not smooth, the noise of the gears is significantly greater.

Inadequate Lubrication

Lubrication is crucial to maintaining plastic gears. It reduces friction between the gear teeth and helps them remain the same shape for longer. When the gear teeth are not lubricated, friction increases. It can generate heat and wear down the teeth’ surfaces. These surfaces then become uneven, increasing the noise they make.

Profile Involute Errors

Profile errors are variations in the gear teeth’ profile compared to the actual, ideal shape. These errors include wear and tear, improper manufacturing processes, deformation due to heat, and contamination. If the shape of the teeth is not the same as the theoretical shape they are supposed to have, the gears might be noisier.

Operating Conditions

Humidity, temperature, and external forces can affect plastic gear noise. Temperature fluctuations can modify the teeth’ dimensions, which can affect gear meshing and lead to noise. High humidity can also impact some types of plastic, which can cause swelling or affect the structural integrity of the gear.

Ways to Reduce Plastic Gear Noise

Lubricate The Gears Properly

One easy way of reducing plastic gear noise is to ensure proper lubrication using the correct type of lubricant. Applying a thick film on the gear surface will help create a barrier between the teeth, preventing direct contact. This separation helps reduce friction and promotes less noise.

Use a High-Precision Gear Design

Focusing on the precision gear design can help manufacturers make gears that work well together so that there is minimal noise. High-precision gears are such that the pitch, tooth profile, and lead errors will not impact the gears’ running. It can lead to less friction and smoother engagement.

Opt for a Better Surface Finish

Improving the surface quality of your gear teeth can help reduce the overall noise that plastic gears make. You can accomplish this by checking whether the gear teeth’ surfaces are smooth. If not, you can ask the manufacturer to remove any imperfections and irregularities beforehand.

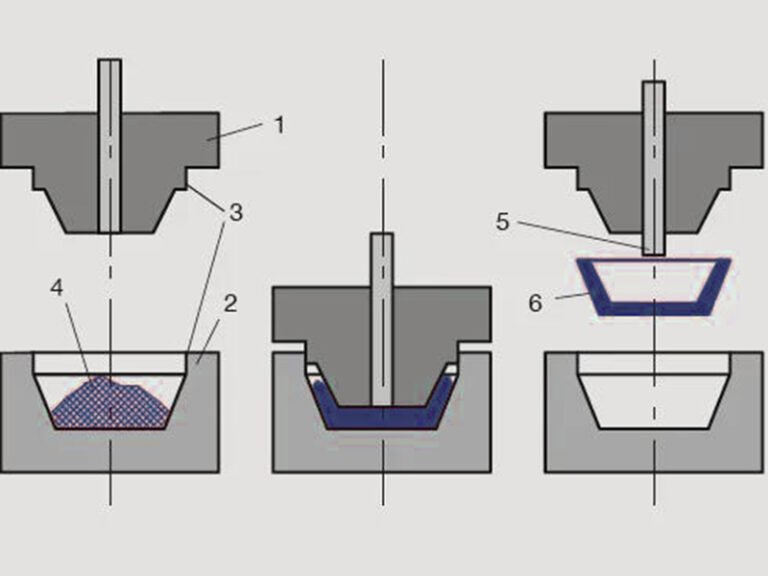

Refine the Gear Tooth Profile

Tooth profile optimization is when the manufacturer modifies the shape of the gear teeth for quieter operation. It mitigates the vibrations that occur when the teeth move together.

We can identify the most severe vibrations with a mathematical model and alter the tooth profile accordingly. It is the most common way of reducing the vibrations.

Use Better Quality Plastic Material

Many kinds of plastic gear are available in the market, but not all options are equally optimal. Material choice has a significant impact on performance and can reduce noise in plastic gears. Opting for high-quality plastic like acetol, POM, or nylon is imperative for the best results. These selections can help dampen both noise and vibrations.

Conclusion

Plastic gears can make lots of noise if not appropriately maintained. However, addressing the factors that lead to noise can help manufacturers design quieter ones.

So, there you have it. We hope this article taught you more about the causes of gear noises and potential solutions!