Polyamide and nylon are two commonly used synthetic polymers with diverse applications across various industries. From textiles to automotive molding components to engineering materials, these polymers play a crucial role in modern manufacturing. While they share similarities in terms of their chemical composition and some properties, they also exhibit distinct characteristics that make them suitable for different applications.

In this post, we will delve into the world of polyamide and nylon, exploring their differences in terms of properties, manufacturing processes, and applications. By understanding these distinctions, we can better appreciate the versatility and utility of these materials in different fields. So, let’s dive in and uncover the unique attributes of polyamide and nylon.

What are Polyamides?

Polyamide, commonly known as nylon, is a synthetic polymer characterized by the presence of repeating amide (CONH) groups in the molecular backbone. Polyamides are known for their high strength, durability, chemical resistance, and low cost, leading to applications in textiles, engineering, automotive, electrical, and 3D printing industries. Polyamides can be produced through various polymerization processes, resulting in different types with distinct properties.

Different Polyamides Types

There are three main types of polyamide: aliphatic, aromatic, and semi-aromatic. Each type has distinct properties and applications:

Aliphatic Polyamides (Nylons)

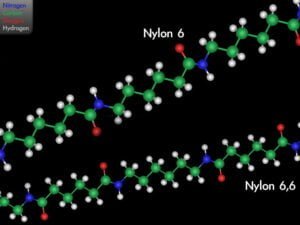

- Examples include nylon 6 (PA 6) and nylon 6,6 (PA 66).

- Have high strength, chemical resistance, flexibility, and low friction.

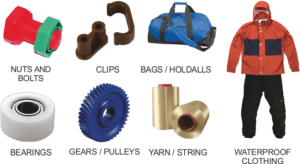

- Used in machine parts, bearings, gears, textiles, automotive components, and packaging.

- Nylon 6 is tough with high tensile strength, produced by ring-opening polymerization.

- Nylon 6,6 has higher melting point and acid resistance than nylon 6.

Aromatic Polyamides (Aramids)

- Examples include Kevlar and Nomex.

- Have much higher strength, chemical resistance, heat resistance, and dimensional stability compared to aliphatic polyamides.

- Used in composite materials for helmets, bulletproof vests, reinforced plastic piping, jet engine inlets, and thermal-resistant fabrics.

Semi-Aromatic Polyamides

- Thermoplastics with semi-crystalline structure combining aliphatic and aromatic polyamides.

- More water resistant, have low creep, and excellent chemical resistance.

- Used in fuel lines, coolant pumps, aircraft engines, fuel cut-off valves, and headlight components.

- In general, polyamides have high strength, flexibility, low density, and good thermal and chemical resistance, making them useful for a wide range of applications from textiles to engineering components.

Polyamide Properties:

- Strength: Polyamides exhibit excellent tensile strength, making them suitable for applications requiring robust materials.

- Flexibility: They are known for their flexibility, allowing them to be molded into various shapes and forms.

- Chemical Resistance: Polyamides demonstrate resistance to many chemicals, oils, and solvents, enhancing their suitability for industrial applications.

- Low Friction Coefficient: They possess a low friction coefficient, making them ideal for applications where smooth surfaces are required.

- Water Absorption: Polyamides have the ability to absorb moisture, which can affect their mechanical properties in certain conditions.

Common Applications of Polyamide:

Polyamide has a wide range of common applications across various industries due to its excellent properties like high strength, durability, flexibility, and chemical resistance. Some of the most common applications of polyamide include:

Textiles and Apparel

- Clothing and sportswear

- Carpets and rugs

- Fishing line and ropes

- Guitar picks and strings

Automotive

- Air intake manifolds and engine covers

- Valve covers and airbag containers

- External components like handles, grilles, wheel covers, fuel caps

- Replacing metal components to reduce weight and improve fuel efficiency

Packaging

- Food and beverage packaging

- Blister packs for medical applications

- Protective packaging

Industrial Applications

- Cable protection systems like conduits and connectors

- Gears and mechanical parts

- Electrical connectors

- Bearings and bushings

- Valves and pumps

Other Applications

- Furniture like stadium seats

- Sports equipment

- Medical implants

- Electrical insulation

What is Nylon?

Nylon is a type of polyamide, specifically a synthetic thermoplastic polymer, that was first developed in the 1930s by a team of researchers led by Wallace Carothers at DuPont. It is a strong, tough, and elastic material that can be fashioned into fibers, filaments, bristles, or sheets.

Nylon Common Properties

Strength and Durability

Nylon has high tensile strength, making it suitable for applications requiring impact resistance and durability. Its high tenacity fibers are used for seatbelts, tire cords, ballistic cloth, and other demanding applications.

Elasticity and Flexibility

Nylon is elastic due to its amorphous regions that contribute elasticity to the plastic. It has high elongation and excellent abrasion resistance.

Chemical Resistance

The strong bonds in nylon make it resistant to most chemicals. It has good resistance to dilute acids, dilute alkalis, oils, greases, and aliphatic hydrocarbons.

Thermal Properties

Nylon is a thermoplastic with a high melting point, typically 215-252°C depending on the type. Heat-stabilized nylon can withstand operating temperatures up to 185°C.

Moisture Absorption

Nylon is hygroscopic and absorbs moisture from the air, which can affect its properties. Moisture absorption tends to increase impact resistance and flexibility while decreasing strength and stiffness.

Luster and Appearance

Nylon can be produced with varying degrees of luster from lustrous to dull. It has a soft “hand” and excellent colorfastness.

Nylon Types and Applications

Nylon 6 (Polyamide 6):

Produced by ring-opening polymerization of caprolactam. It is tough with high tensile strength, softness, flexibility, and moisture-wicking.

Uses: Nylon 6 is widely used in textile applications, including clothing, hosiery, and sportswear. It is also utilized in engineering plastics for automotive components, electrical insulators, and consumer goods.

Nylon 6,6 (Polyamide 6,6):

It is made from hexamethylenediamine and adipic acid, and Nylon 66 has a higher melting point and acid resistance than nylon 6. It is the most common commercial grade of nylon.

Uses: Nylon 6,6 is known for its exceptional strength, stiffness, and heat resistance, making it suitable for demanding applications such as automotive parts, mechanical components, and industrial equipment. It is also used in textiles for applications requiring high durability and abrasion resistance, such as carpets and upholstery.

Nylon 11 (Polyamide 11):

Nylon 11 has increased resistance to dimensional changes from moisture absorption, making it ideal for applications in harsh environments.

Uses: Nylon 11 is commonly used in oil and gas exploration, automotive fuel lines, pneumatic tubing, and industrial coatings.

Nylon 12 (Polyamide 12):

It has the lowest melting point of the main polyamides. Nylon 12 also offers excellent impact resistance, abrasion resistance, and low permeability to gases.

Uses: It is used in automotive fuel lines, hydraulic tubing, air brake systems, and flexible hoses. It is also used in sports equipment, medical devices, and electrical insulation.

Each type of nylon offers unique properties that cater to specific application needs, ranging from textiles and consumer goods to automotive and industrial components. The choice of nylon type depends on factors such as mechanical strength, chemical resistance, flexibility, and environmental considerations.

Polyamides and Nylon: the Main Differences

Polyamides and nylons are often used interchangeably, but technically, nylon is a type of polyamide. Here are some differences between the two materials.

Polyamide: Polyamide is a generic term used to describe any polymer containing recurring amide groups (-CONH-) in the molecular backbone. It encompasses a broad range of polymers, including nylons.

Nylon: Nylon specifically refers to a subset of polyamides, synthetic aliphatic polyamides, characterized by their toughness, strength, and elasticity.

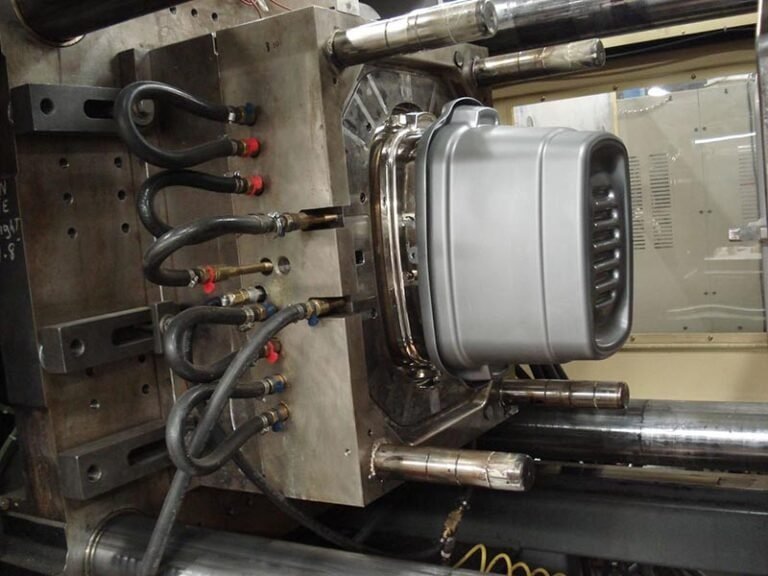

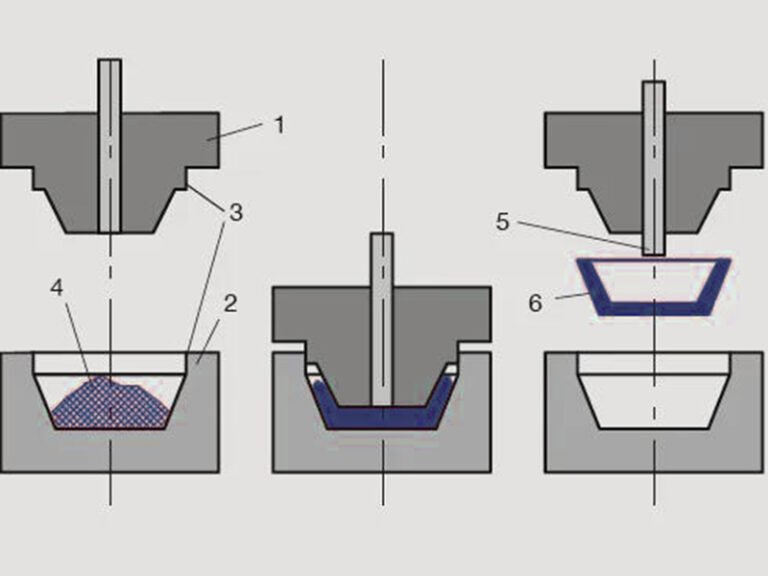

Plastic Molding Process:

Conventional plastic molding processes such as injection molding, extrusion molding, blow molding, compression molding, thermoforming, and 3D printing can be applied to Polyamide and Nylon. They can reach a plastic state when heated, making them easy to process. Let know more about the difference between with polyamide and nylon in molding plastic.

1. Differences in melting points:

Nylon 6 has a lower melting point (approx. 220°C), which gives it better flow during processing and makes it suitable for thin-walled products.

Nylon 66 has a higher melting point (about 260°C), so it has better strength and heat resistance after molding at high temperatures, but the processing conditions are harsher and require higher temperatures and pressures.

2. Differences in water absorption and drying treatments:

There are differences in the water absorption of the different types of polyamides in Polyamide, with aliphatic polyamides (e.g., Nylon) having a high degree of hygroscopicity and aromatic polyamides (e.g., Kevlar) having a low degree of hygroscopicity.

Nylon (specifically aliphatic polyamides) has a relatively high water absorption, especially Nylon 6, which is slightly more hygroscopic than Nylon 66. This results in the need for drying prior to molding, otherwise evaporation of water during high temperature processing will result in bubbles and surface defects.

3. Differences in processing fluidity and molding process:

The processing flow of polyamide (which includes different types of polyamides) varies according to the structure of the material:

Aromatic polyamides have poor melt flow and are therefore unsuitable for conventional injection molding and extrusion processes and require more specific processing conditions.

Nylon:

Nylon 6 is suitable for complex shapes or thin-walled products due to its low melting point and good flow in injection and extrusion molding.

Nylon 66 melting point is higher, fluidity than Nylon 6 poor, but the mechanical strength and heat resistance of the molded product is higher, suitable for high-strength, abrasion resistance and heat resistance requirements of higher products.

4. Differences in molding temperature and process control:

Polyamide (other polyamide materials):

Aromatic polyamides (e.g. Kevlar): very high molding temperatures, usually for specific high-performance products, and relatively complex molding equipment requirements.

Nylon: Molding temperatures typically range from 240°C to 280°C, depending on the material grade:

5. Differences in cooling rates and product properties:

Different types of Polyamide behave differently in terms of cooling rate, which affects the crystallinity and mechanical properties of the finished product.

The crystallinity of Nylon has a significant effect on its final mechanical strength and heat resistance:

Nylon 6 takes longer to cool due to slower crystallization rates, but has better crystalline homogeneity and better toughness of the finished product.

Nylon 66, with its rapid cooling and high crystallinity, has relatively better rigidity and hardness of the finished product, but may develop internal stresses under rapid cooling.

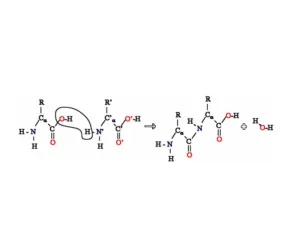

Synthesis:

Polyamide: Polyamides can be synthesized from a variety of monomers, resulting in different types of polyamides with distinct properties. These monomers can include diamines and dicarboxylic acids or amino acids.

Nylon: Nylon is typically produced through the condensation polymerization of diamines and dicarboxylic acids or through the ring-opening polymerization of lactams. The specific monomers and polymerization process used determine the properties of the resulting nylon.

Properties:

Polyamide: Polyamides exhibit a wide range of properties depending on their chemical composition and structure. They can vary in terms of strength, flexibility, chemical resistance, and other characteristics.

Nylon: Nylon, being a type of polyamide, shares many properties with other polyamides but is characterized by its exceptional strength, durability, flexibility, and abrasion resistance. Nylons typically have a higher melting point and better mechanical properties compared to other polyamides.

Applications:

Polyamide: Polyamides find applications in various industries, including textiles, automotive, aerospace, electronics, and consumer goods. They are used for a wide range of products such as clothing, carpets, automotive parts, electrical insulation, and packaging materials.

Nylon: Nylons are specifically valued for their toughness, elasticity, and low friction coefficient, making them suitable for applications requiring high strength, durability, and wear resistance. Common uses of nylon include textiles, engineering plastics, automotive components, industrial equipment, and consumer goods.

Polyamide vs. Nylon: Which is Better?Conclusion

The exploration of polyamide and nylon reveals two versatile classes of synthetic polymers. While both polyamides and nylons share similarities in their molecular structure and some properties, they also exhibit distinct characteristics that make them suitable for different applications.

Understanding the differences between polyamides and nylons is crucial for selecting the right material for specific applications. Whether it’s the flexibility of nylon in textile manufacturing, the durability of nylon in automotive engineering, or the chemical resistance of polyamides in industrial settings, these materials continue to play a vital role in modern manufacturing processes.