Snap fits in plastic parts are a popular and efficient way to connect two components, especially in an injection molding type. They work by using the flexible nature of plastic to create secure joints without the need for screws or glue. The snap-fit has different types and offers several benefits. In this post, we will explore the basics of snap fits in plastic parts, their advantages, types, and design tips. Hope the guide will provide valuable insights.

What are Snap Fits in Plastic Parts?

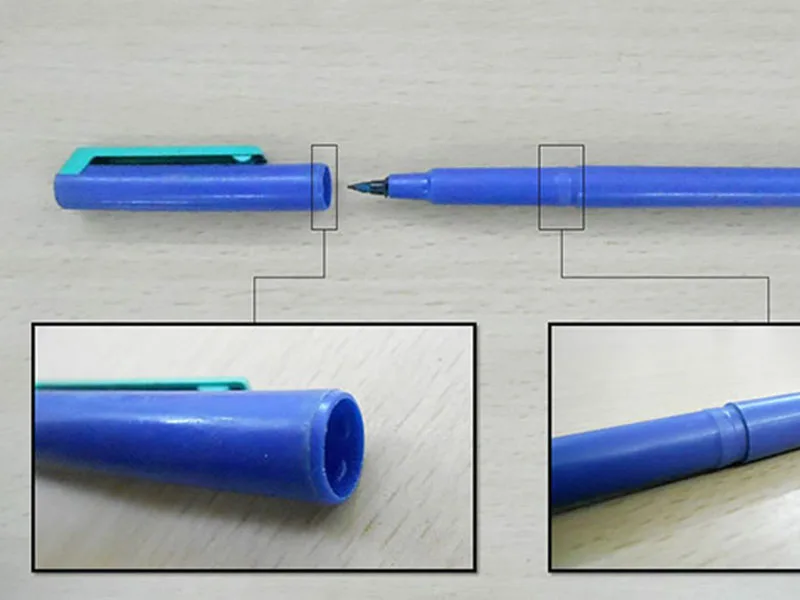

Snap fits are an assembly method used to attach flexible plastic parts by pushing their interlocking components together. A snap-fit joint consists of a protrusion (often called a cantilever snap) on one flexible plastic part that deflects and snaps into a groove or undercut on the mating part during assembly.

What Plastics are Best for Snap Fits in Plastic Parts?

Choosing the right plastic molding material is crucial for designing effective snap fits in plastic parts. The material must possess specific properties, including flexibility, strength, and durability, to ensure reliable performance. Here are some of the best materials commonly used for snap fits:

1. Polypropylene (PP)

- Flexibility: Polypropylene is highly flexible and can withstand repeated bending without breaking, making it ideal for snap fits.

- Durability: It offers good fatigue resistance, which is essential for parts that will be snapped and unsnapped multiple times.

- Cost-Effective: Polypropylene is relatively inexpensive, making it a cost-effective choice for high-volume manufacturing.

2. Polycarbonate (PC)

- Strength: Polycarbonate is known for its high strength and toughness, which makes it suitable for snap fits that require more robust connections.

- Transparency: It is often used in applications where transparency is needed, such as in clear covers or housings.

- Impact Resistance: Polycarbonate has excellent impact resistance, ensuring durability even under harsh conditions.

3. Acetal (Polyoxymethylene, POM)

- Low Friction: Acetal has low friction and good wear resistance, which helps in smooth snapping and unsnapping actions.

- Dimensional Stability: It offers excellent dimensional stability, ensuring consistent performance of snap fits.

- Strength and Rigidity: Acetal provides a good balance of strength and rigidity, making it suitable for precise and reliable snap-fit designs.

4. Nylon (Polyamide, PA)

- Toughness: Nylon is very tough and can withstand high stress, making it ideal for snap fits in demanding applications.

- Chemical Resistance: It has good resistance to a wide range of chemicals, which is beneficial in environments where exposure to solvents or oils is expected.

- Fatigue Resistance: Nylon performs well under cyclic loading, ensuring the longevity of the snap-fit connections.

5. ABS (Acrylonitrile Butadiene Styrene)

- Impact Resistance: ABS offers good impact resistance and toughness, making it suitable for parts that may experience rough handling.

- Ease of Molding: It is easy to mold, allowing for complex snap-fit designs.

- Aesthetic Quality: ABS can be finished with a smooth surface, providing a good appearance for consumer products.

What are the Advantages of Snap Fits in Plastic Parts?

Snap fits offer several advantages when used to assemble plastic parts:

- Easy assembly and disassembly – Parts simply snap together without the need for separate fasteners like screws or bolts, making assembly quicker and easier.

- Improved aesthetics – Snap fits provide a seamless appearance with no visible fasteners, enhancing the overall look and feel of the product.

- Cost savings – Eliminates the need to purchase separate fasteners and reduces assembly labor costs.

- Fewer components – No additional fasteners are required, reducing part count and complexity.

- Temporary or permanent joints – Snap fits can be designed for repeated assembly/disassembly or permanent locking joints.

- Design flexibility – Snap features can be molded integrally into plastic parts during injection molding.

- Vibration resistance – Once snapped together, joints resist vibration and stay securely locked.

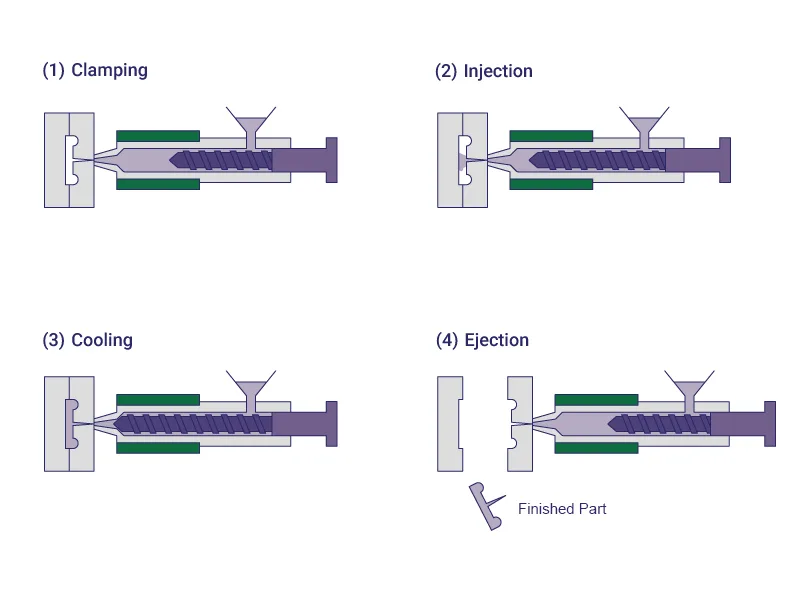

- Simplified Manufacturing Process-Snap fits can be easily incorporated into the design of injection-molded parts, simplifying the manufacturing process and reducing production complexity.

What are the Disadvantages of Snap Fits in Plastic Parts?

While snap-fit plastic parts offer many advantages, they also come with certain drawbacks. Here are some key disadvantages of using snap fits in plastic parts:

- Design complexity – Proper snap fit design requires careful consideration of material properties, deflections, undercuts, and radii to avoid excessive stress concentrations.

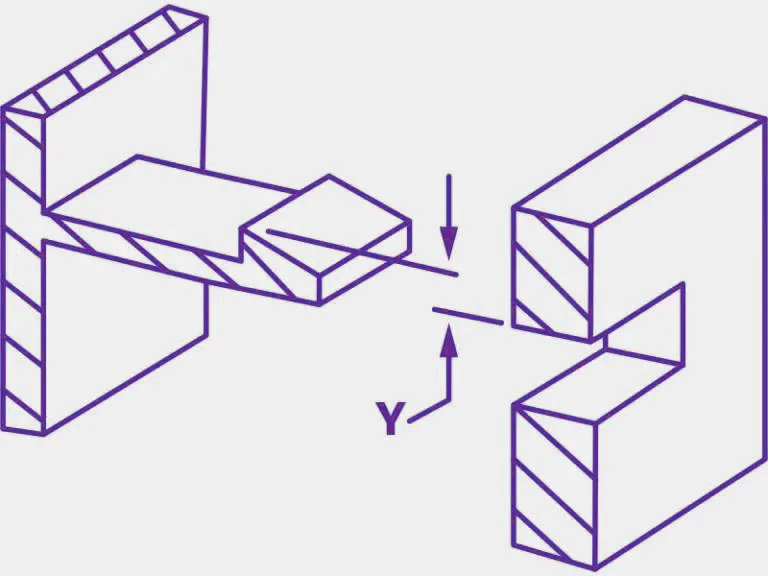

- Undercuts increase mold complexity and cost – Snap fit features like hooks and grooves require undercuts in the mold tool, making it more complex and expensive to manufacture.

- Potential for snap breakage – If overstressed during assembly or disassembly, the flexible snap features can break, requiring part replacement.

- Not as strong as screws/fasteners – Snap fits are not as robust as using separate screws or fastener hardware, especially for high-load applications.

What are the Types of Snap Fits?

Snap fits come in various designs, each tailored to specific applications and design requirements. Here are the four main types:

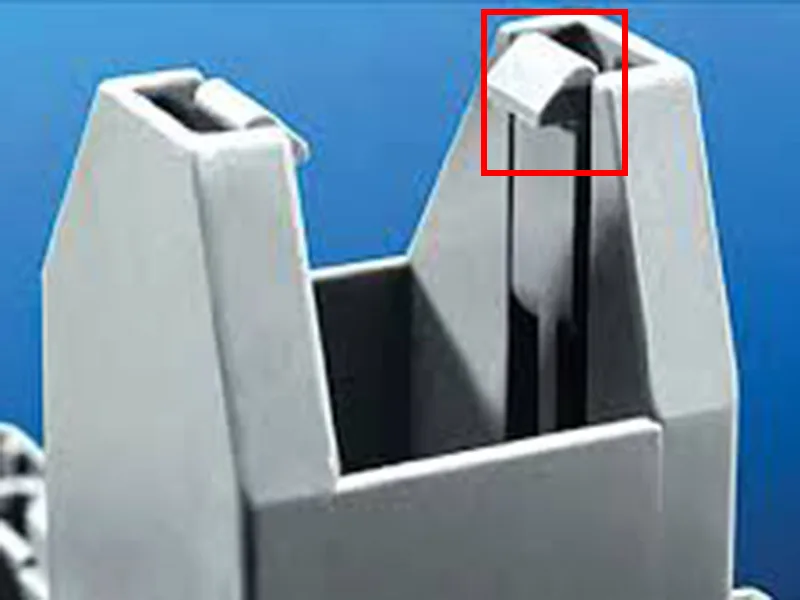

1. Cantilever Snap Fits

Cantilever snap fits are the most common type. They consist of a protruding beam (the cantilever) on one part that snaps into a corresponding slot or notch on the mating part.

During assembly, the cantilever beam deflects as the hook slides over the mating part until it snaps into an undercut groove or cavity, creating a secure connection. Cantilever snaps can have straight, L-shaped, or U-shaped beams.

Common Applications of cantilever snap fit joint:

Electronic enclosures

Battery covers

Automotive interior panels

Design Considerations with Plastic Snap Fit:

- Beam Length and Thickness: The length and thickness of the cantilever beam must be carefully designed to balance flexibility and strength.

- Material Selection: Use materials with good fatigue resistance and flexibility, such as polypropylene or polycarbonate.

- Stress Distribution: Ensure that the stress is evenly distributed along the beam to avoid concentration points that could lead to failure.

- Engagement Force: Design the snap-fit to require an appropriate amount of force for assembly and disassembly, ensuring it is user-friendly and secure.

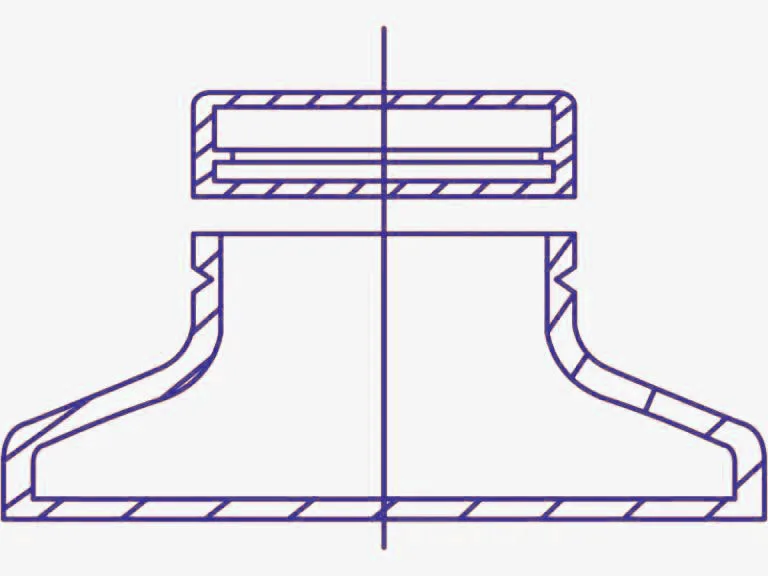

2. Annular Snap Fits

Annular snap fits use a circular or ring-shaped protrusion on one part that snaps into a corresponding groove or recess on the mating part.

The annular feature deforms elastically as it passes over the mating feature and then snaps back into place to form a secure connection similar to bottle caps.

Common Applications of Annular Snap Fit:

- Lids and caps for containers

- Hose connections

- Seals for enclosures

Design Considerations with Plastic Snap Fit:

- Circular Geometry: Ensure the circular features are precisely designed to maintain consistent engagement and force distribution.

- Material Selection: Choose materials with good elasticity and recovery properties, such as acetal or nylon.

- Engagement and Disengagement Force: Design the snap fit to provide a secure seal while allowing for easy manual assembly and disassembly.

- Tolerance Control: Maintain tight tolerances to ensure reliable snap engagement and prevent leakage or loosening.

3. Torsional Snap Fits

Torsional snap fits involve a twisting section where a tab or hook on one part rotates and snaps into a slot or notch on the mating part. The torsional motion causes the snap feature to twist and then lock into place, providing a secure connection.

Common Applications of Torsion Snap Joints:

- Rotating lids or covers

- Hinged enclosures

- Adjustable components

Design Considerations with Plastic Snap Joints:

- Torsional Flexibility: The snap feature must be able to twist sufficiently without breaking or permanently deforming.

- Material Selection: Use materials with good torsional strength and fatigue resistance, such as polycarbonate or ABS.

- Engagement Mechanics: Ensure the twisting motion required for engagement is intuitive and can be easily performed by the user.

- Durability: Design the snap fit to withstand repeated twisting motions without degradation.

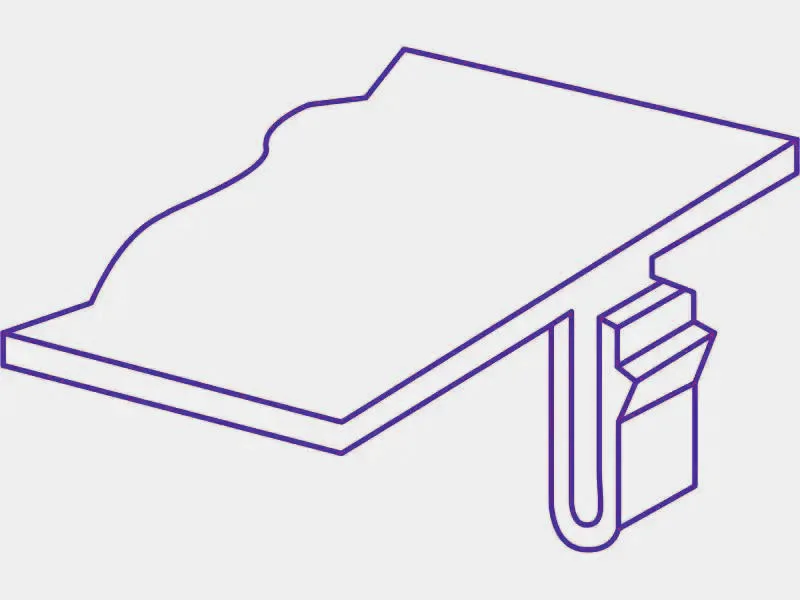

4. U-Shaped Snap Fits

U-shaped snap fits consist of a U-shaped feature on one part that snaps into a corresponding slot or notch on the mating part.

The U-shaped feature flexes inward during assembly and then snaps outward into place, securing the connection.

Common Applications of U-Shaped Snap Fit:

- Clip-on covers

- Cable management clips

- Modular assembly parts

Design Considerations with Plastic Snap Fit:

- Flexural Properties: The U-shaped feature must have sufficient flexural properties to snap into place without cracking.

- Material Selection: Choose materials with good flexibility and impact resistance, such as polypropylene or nylon.

- Stress Distribution: Design the U-shaped feature to distribute stress evenly during flexing to prevent failure.

- Ease of Assembly: Ensure the U-shaped snap fit can be easily engaged and disengaged by the user without excessive force.

Design Principles for Snap Fits

Here are some key design principles to follow when designing snap fits in plastic parts with injection molding:

Select a Suitable Material:

- Choose plastics with good flexibility, impact resistance, and fatigue strength, like polyoxymethylene (POM/acetal), nylons (polyamides), and polypropylene (PP).

- Partially crystalline polymers like nylons can deflect closer to their yield point compared to amorphous polymers during snap fitting.

- Review S-N fatigue curves to ensure the material can withstand the intended number of snap cycles without failure.

Geometry Optimization:

- Use generous radii to reduce stress concentrations, especially at the base of cantilever snap beams.

- Increase snap beam length to allow more deflection with less strain.

- Reduce snap cross-section thickness to increase flexibility and deflection.

Deflection Control:

- Size deflections to stay within working stress levels and below yield strain for the chosen plastic.

- For amorphous plastics, limit deflection to ~70% of yield strain during snap fitting.

- Partially crystalline plastics can deflect closer to the yield point for a single snap operation.

Optimize Undercut Design:

- Minimize undercuts in mold tools to reduce complexity and cost.

- Design snaps in the line of draw when possible to avoid side actions.

- Provide adequate draft angles for undercut surfaces.

Other Considerations:

- Add opening aids like grip extensions to facilitate disassembly by hand.

- Avoid sharp edges that could cause injury during assembly.

- Account for manufacturing tolerances in snap-fit dimensions.

Plastic Snap Fits Molding Conclusion

Snap fits provide a convenient and cost-effective method for assembling plastic components without separate fasteners. By taking advantage of the flexibility of plastic materials, snap fit joints allow parts to be snapped together using precisely designed interlocking features like protruding hooks, grooves, and undercuts. Cooperate with experienced manufacturers with Flexiparts, choose the right materials and snap fit types, and design a perfect snap fit in plastic parts.