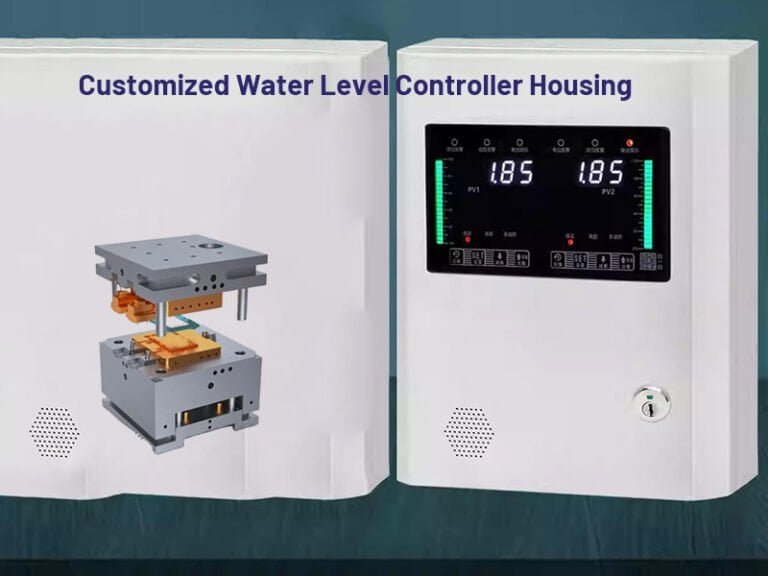

The water level controller housing protects the water level controller system from water and outdoor UV damage. It is an important part of water level controllers. This post will introduce our high-quality custom water level controller enclosures.

Water Level Controller Housing Structure and Size

The water level controller shell is meticulously designed using ABS plastic injection molding, which provides insulation and waterproofing. The enclosure consists of two main parts: the front and back shells. The back shell is flat and designed for secure wall mounting, while the front shell features screw slots at each corner for easy assembly.

The front of the enclosure includes a water level display screen or indicator lights, along with control buttons for various functions. The power socket is conveniently located beneath the shell.

In terms of dimensions, the water level controller shell typically measures:

Length: 15-17 cm

Width: 9-11 cm

Height: 2-4 cm

The display can be square or fan-shaped, with a standard square area measuring 2-5 cm in length and 2-4 cm in width.

We can also customize manufacturing the different sizes and structures based on your specific requirements.

Why ABS for Water Level Controller Housing

Given that water level controllers are often used outdoors, the materials used for the water level controller shell must withstand varying weather conditions. Such as waterproof, and resistant to high temperatures and UV Damages. ABS plastic is our material of choice for injection molding due to several advantageous properties:

1. Durability and Impact Resistance

ABS plastic is renowned for its excellent impact resistance, ensuring the water level controller shell can withstand physical stresses and impacts without cracking or breaking. This durability is crucial for devices exposed to varying environmental conditions, ensuring long-term reliability and performance.

2. Chemical and Thermal Stability

The composition of ABS provides good chemical resistance, making it suitable for environments where exposure to various chemicals may occur. Additionally, ABS maintains its structural integrity across a wide temperature range, typically from -40°C to 80°C, which is beneficial for outdoor applications where temperature fluctuations are common.

3. Waterproof and Insulation Properties

The high density of ABS plastic contributes to its waterproof capabilities, preventing water ingress and protecting the internal components of the water level controller. Moreover, ABS offers excellent electrical insulation, which is essential for safety in electrical applications.

4. Ease of Molding and Customization

ABS plastic is easily molded and shaped through injection molding, allowing for intricate designs and precise dimensions. This adaptability facilitates the production of custom water level controller shells tailored to specific requirements, enhancing both functionality and aesthetics.

5. Cost-Effectiveness

The production costs of ABS plastic are relatively low compared to other materials, making it a cost-effective option for manufacturers. Its ability to be produced in large quantities without compromising quality further reduces the overall cost, making it an economical choice for mass production.

6. Aesthetic Appeal

ABS can be finished to achieve a smooth, glossy surface that is visually appealing. This quality is important for consumer-facing products, where appearance can influence purchasing decisions.

Advantages of Our Water Level Controller Shell Production

Advanced Technology: We utilize professional injection molding equipment and cutting-edge production techniques to create custom-designed water level controller housings based on client specifications.

Professional Team: We have a professional R&D team to solve customers’ unique requirements.

Streamlined Production Process: Our engineers oversee each step of the production process, from planning and design to manufacturing, ensuring quality control at every stage.

Wide Range of Services: We offer mold design and production, assembly and packing, etc. The size and structure are customized. The product is accurate to ±0.05mm.