Custom Polyurethane Molding Products and Services

Erye has been in the polyurethane molding industry for over 40 years, producing high-quality custom urethane molded parts for a wide variety of customers in different industries. Each urethane or polyurethane product produced by Jiangzhi is precision crafted using only the finest quality urethane materials, and no matter how large or small the project is, we will ensure that the final customized product matches the customer’s needs.

Polyurethane Properties

Polyurethane is a high-quality material with many excellent properties, superior in many ways to plastics, rubber, and metals.

- Resilient

- Durable

- Cost Effective

- Abrasion Resistant

- Impact Resistant

- Chemical and Oil Resistant

- Non-absorptive

- Non-conductive

- Vibration and Shock Dampening

- Extremely Versatile

Our Manufacturing Process of Urethane Parts

Urethane Compression Molding

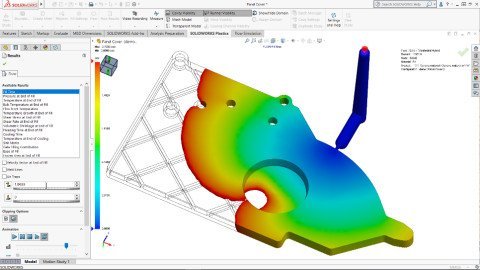

The process involves pouring liquid polyurethane into a mold and curing it using a compression press with capacities of up to 250 tons. This method is particularly well-suited for components that require precise dimensional accuracy and consistent repeatability.Urethane Injection Molding

Liquid polyurethane is injected into a sealed mold at low pressure, offering an ideal method for projects where compression molding might prove impractical due to factors like component size, shape, or tooling configuration.Urethane Cast Molding

Pouring into an exposed mold, subsequently cured either in an oven or on a heated table. This method is applicable to part sizes ranging from less than an ounce to over 500 lbs, proving advantageous for projects where conventional tooling would be costly or unfeasible.Work with Erye to Make Custom Plastic Housing

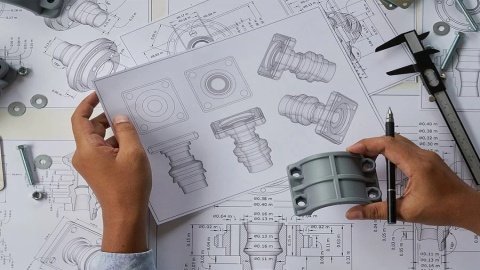

Design drawings according to product functions;

Send us the required drawing and get a quote;

Open a new mold;

Make a prototype and sample testing;

Mass production and quality control.