Polyurethane Cast Molding

What is Urethane Casting?

Urethane casting, also known as polyurethane casting or cast molding, is a versatile manufacturing process. It entails producing top-quality prototypes and low-volume production components by pouring liquid urethane material into molds to form objects. This technique is employed to craft a wide range of items, from small-scale prototypes to intricate parts.

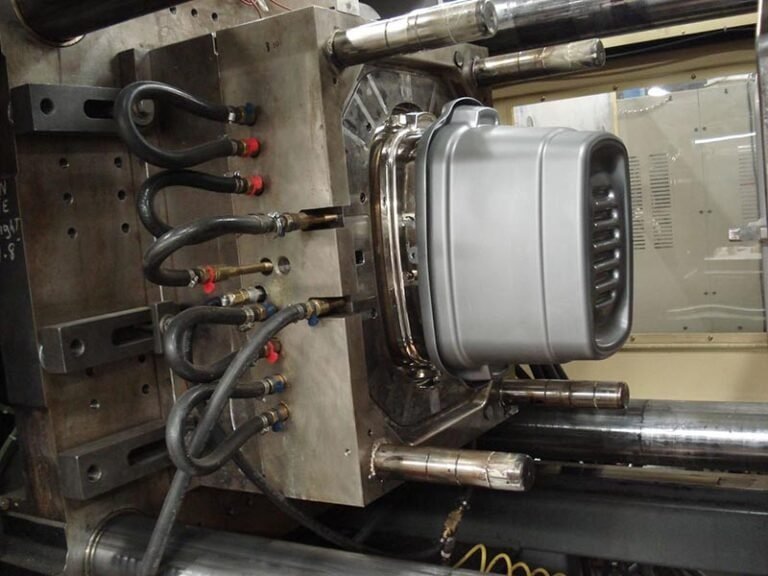

Cast Urethane Molding Working Process

Mold Creation for Precision: We begin by crafting a mold designed to perfectly replicate the desired part, ensuring all intricate details are captured accurately.

Expert Material Mixing and Pouring: Our skilled technicians masterfully mix and pour polyurethane molding material, ensuring it fills every cavity for a flawless part.

Curing for Quality: During curing, the material solidifies, acquiring the intended shape and unmatched quality.

Careful Demolding and Refinement: After curing, we expertly demold the part, then apply meticulous finishing touches for a refined, high-quality product.

Urethane Casting Options

Urethane casting is a highly versatile process that allows for the precision creation of customized parts. We specialize in providing tailored solutions to meet your unique requirements. With a wide range of color options, customizable finishes, versatile resins, and value-added extras, our focus is on delivering precision and customization to bring your projects to life.

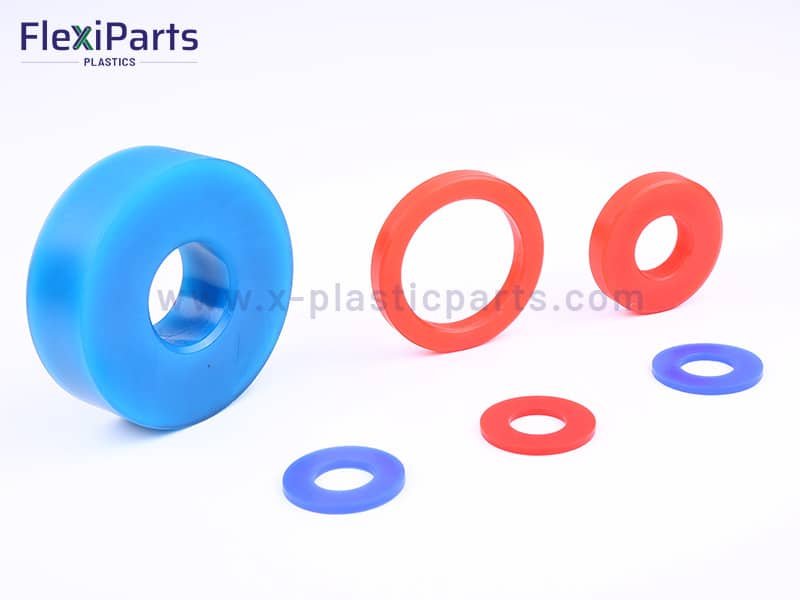

Versatile Color Options

Choose from a wide array of colors to suit your project's aesthetics. We also offer the option for customers to provide color samples for exact color matching.

Custom Surface Finishes

Achieve the exact texture and finish you desire for your parts. Our urethane casting process allows for precise customization of mold textures like SPI, VDI.

Material

Unlike CNC machining, urethane casting has limitations on material compatibility. Our urethane casting capabilities encompass rigid materials in Shore D and elastomeric options in Shore A resin,

Value-added Options

We offer value-added options such as spray painting, pad printing, screen printing, assembly, and more to meet additional requirements for your parts.

Custom Plastic Parts

Custom Rubber Parts

Custom PU Parts

Application and Examples of Urethane Casting

Urethane injection molding parts is a versatile process employed in various industries, offering tailored solutions for a wide range of applications. We have extensive experience in urethane casting, serving diverse sectors with precision-engineered solutions.

Automotive Parts

- Custom Gaskets: Urethane casting is utilized to create custom gaskets, ensuring reliable sealing in automotive applications.

- Interior Trim: Interior trim components, such as dashboard parts and door handles, benefit from urethane casting for intricate designs.

Electronics Enclosures

- Prototypes and Housings: Urethane casting enables the rapid production of prototypes and housings for electronic devices.

- Button Panels: Complex button panels with unique textures and finishes are efficiently manufactured using this method.

Consumer Products

- Consumer Electronics: The casing for consumer electronics, such as remote controls and smart devices, is manufactured using urethane casting.

- Toys and Collectibles: Urethane casting enables the creation of detailed and durable toy and collectible components.

Industrial Equipment

- Equipment Handles: Ergonomic equipment handles with non-slip surfaces are efficiently produced using this method.

- Wear-Resistant Components: Urethane casting is ideal for producing wear-resistant components in industrial settings.

Related Resources

Our Available Material

Urethane Casting Parts We Made