Compression Molding

What is Compression Molding?

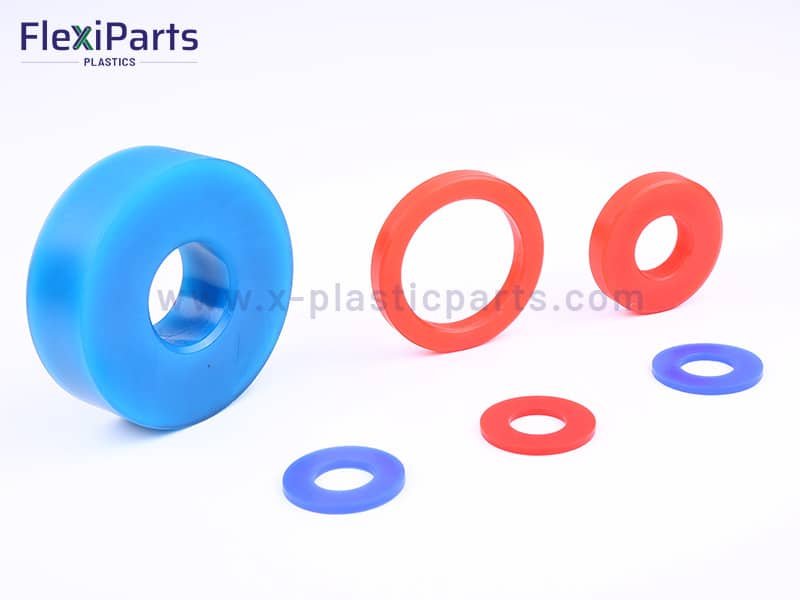

Compression molding is a flexible manufacturing process used to create a wide range of products from materials such as plastics, rubber silicone and composites. Such as parts of gaskets, seals, and intricate medical components. It involves placing the material into a heated mold cavity, applying pressure, and maintaining heat until the material cures, solidifies, or achieves the desired shape and properties.

This method is known for its ability to produce complex and precise components with consistent quality. It’s widely used in industries where precision, durability, and cost-effectiveness are crucial, such as automotive, aerospace, and electronics.

Compression Molding Working Process

- Mold design and Creation: The first step in compression molding is to design the mold. According to your product requirements, we will design and create a metal mold that matches the shape and size of your product. Molds can be produced by machining, die-casting, and 3D printing.

- Preparation of Raw Material: According to the function of your product, Preparing raw materials, typically thermosetting polymers or thermoplastics, operators cut materials into modules of different lengths and widths according to the weight of the product.

- Loading and Mold Closure: Place the prepared material into the mold cavity and apply hydraulic pressure to firmly seal the mold, ensuring the material takes the intended shape.

- Heating and Controlled Compression: Soften the material within the mold by methodically applying heat while precisely controlling pressure to compress it into the desired form.

- Curing and Demolding: Allow the material to solidify within the mold cavity, it is cooled and removed from the mold. According to the needs of the product, flash or trim.

- Thorough Quality Inspection: Rigorously inspect finished parts to guarantee each component meets stringent specifications and maintains the highest quality standards.

Compression Molding Parts Material

With Flexiparts Plastic’s experienced engineers, we will provide expert selection and advice on compression molding manufacturing requirements from (Silicone, ). The ability to reliably produce high volume molded products while minimizing scrap and losses.

If your project requires materials not listed here, please contact our service team!

Key factors to consider when selecting materials include

- Hardness: Determines the hardness and flexibility of the final part.

- Temperature resistance: Ensures that the material can withstand the working conditions.

- Chemical resistance: Prevents degradation from exposure to various substances.

- Tear strength: Affects the durability and damage resistance of the part.

Conventional compression molded rubber materials

Silicone Rubber

EPDM Rubber

Neoprene Rubber (CR)

Nitrile Rubber (NBR)

Natural Rubber (NR)

Styrene-Butadiene Rubber (SBR)

Butyl Rubber (IIR)

Conventional compression molded plastics materials

Prolypropylene (PP)

Polyamide (Nylon)

UHMWPE

HDPE

Custom Plastic Parts

Custom Rubber Parts

Custom PU Parts

LET’S START A NEW COMPRESSION MOLDED PARTS

Application and Examples of Compression Molding

Compression molded product is employed across diverse industries. Our experience in custom compression molding spans a diverse range of products, serving numerous sectors with precision-engineered solutions

Automotive Components

- Brake Pads: Compression molding is used to manufacture brake pads for automobiles, ensuring they are durable and heat-resistant.

- Engine Gaskets: Engine gaskets, such as head gaskets and intake manifold gaskets, are often made using compression molding for reliable sealing.

- Rubber Bushings: Rubber bushings for suspension systems and engine mounts are produced through compression molding.

Electrical Insulators

- Switchgear Components: Compression molding is employed to create insulating components used in switchgear assemblies.

- Fuse Holders: Insulating fuse holders that provide electrical safety are commonly produced using compression molding.

- Terminal Blocks: Terminal blocks for electrical connections are manufactured with precision through compression molding.

Medical Devices

- Dental Products: Items like denture bases and orthodontic devices are made using compression molding for biocompatibility.

- Pharmaceutical Packaging: Some types of pharmaceutical packaging, like rubber stoppers for vials, are created through compression molding.

- Medical Gaskets: Compression-molded gaskets are used in medical equipment to ensure sealing and hygiene.

Aerospace Components

- Grommets and Seals: Aerospace applications often require custom grommets and seals, which are precisely manufactured using compression molding.

- Interior Panels: Certain interior components, like panels and trim, are made using this method for lightweight yet durable solutions.

- Cable Insulators: Compression-molded cable insulators are used to protect wiring and ensure electrical safety in aircraft.

Related Resources

Our Available Material

Why You Should Choose Compression Moulding?

1. Simplicity in Manufacturing

Compression molding services simplifies the manufacturing process, reducing complexity compared to other methods.

2. Cost-Efficient Tooling

This technique offers cost-effective tooling solutions, making it ideal for projects with budget considerations.

3. Suitable for Large and Thick Parts

Compression molding excels in producing large and thick components without compromising quality.

4. Versatile for Insert and Multi-Color Molding

It is a versatile choice, especially useful for insert molding and multi-color molding applications.

What is Downside of Compression Molding?

1. Potential for Additional Post-Molding Costs

Depending on design complexity, compression molding may lead to post-molding expenses, such as trimming or finishing.

2. Extended Processing Times

This method generally involves longer processing times compared to alternative techniques, impacting production speed.

3. Limitations in Complex Designs

Compression molding service may not be suitable for highly intricate or complex designs, limiting its use in certain projects.

Compression Molded Products We Made